Gator Tile System

Innovative and durable 7 components system

for outdoor porcelain tile installation

- Large-format outdoor porcelain tiles

- Residential applications

- All pedestrian uses: patio, pool deck, walkway

- Replacing a concrete slab

- Evacuating water through the channel

- The environment the Gator Base is 100% recyclable

- Facilitates the installation of outdoor porcelain tiles

- Easiest outdoor tile installation system

- Complete the job faster

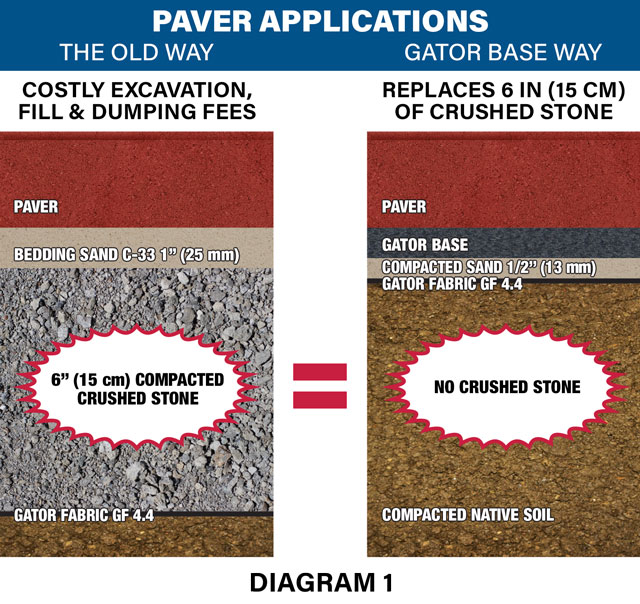

- Replacing the excavation and backfill of of 6″ (15 cm) of crushed stone

- Lock-in system with spacers, glued, to the tiles, creating a monolithic surface

- The Gator Base designed tongue-and-groove system

- Replacing the equivalent of 288 lb (130 kg) of crushed stone per unit of Gator Base

THE 7 COMPONENTS OF THE SYSTEM

1

Prevents migration of the bedding sand or chip stone into the native soil.

GATOR FABRIC GF4.4 (100 lbf) is a needle punched non-woven geotextile made of polypropylene fibers. GATOR FABRIC GF4.4 geotextile is ideal for drainage, filtration and will allow water flow of 135 gallons per minutes per square foot (613 L/min/sq. m.) in paver or retaining wall applications. Its filament fibers are used for soil separation and drainage. They combine high durability along with excellent physical and hydraulic properties. It is non-biodegradable and resistant to most soil chemicals.

- Porcelain tile sub base foundation

- Gator Base foundation application

- Protection against erosion

- Drainage control

- Soil separation

- General landscape

- Specially treated to be hydrophilic, it allows high-water flow (135 Gal/min/sq. ft. (613 L/min/sq. m.))

- Drainage and filtration

- Soil separation

- Erosion control

- UV-Resistance

- Inert to soil chemicals (Alkalis, Acids)

- Inert to biological degradation

- Easy to handle

- High strength/dimensionally stable

2

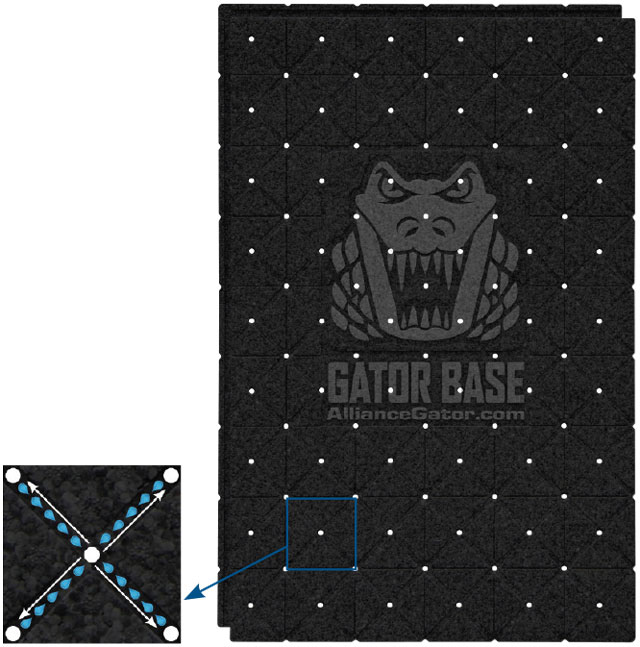

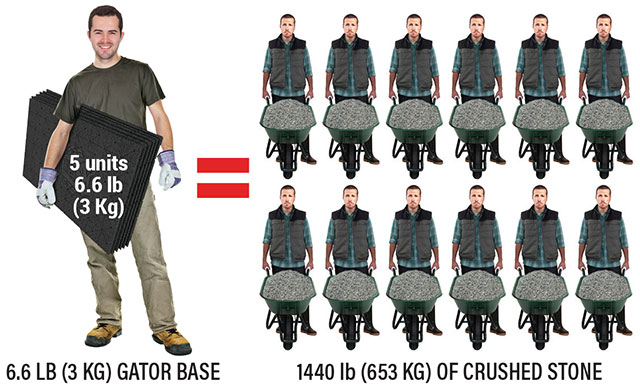

Engineered to replace 6" (15 cm) of compacted crushed stone.

- Save 6″ (15 cm) of additional excavation

- Save 6″ (15 cm) of compacted crushed stone

- 50% savings on the costs of soil excavation

- Save the cost of truck and driver on the road

- Avoids costly unloading and dumping fees

- Reduces labor costs by a minimum of 20%

- Reduces wear and tear on machinery

- Reduces overall installation time

- Reduces unnecessary excavation

- Project completed faster and easier

- Gator Base panels help transfer dynamic and static loads

- Helps to combat the labor shortage

- Take Note: For pedestrian use only

- Manufactured using lightweight high-density polypropylene

- Has an R-Value of 3.6 which acts as a thermal blanket

- Is extremely durable and will not degrade in the ground

- Equivalent to 288 lb (130 kg) of crushed stone

- Designed with a tongue and groove system LOCK-N-GO

- Replaces 6″ (15 cm) of compacted crushed stone

- Designed for pedestrian applications only

- Water evacuation channels

- Covers 5.79 sq. ft. (0.54 sq. m.) per panel

- Watch our video

Water evacuation channels

Under License from Brock International Patented and Patents Pending: www.brockpaverbase.com

- Gator Base replaces 6″ (15 cm) of crushed stone!

- Saves hours of work!

- Installation on compacted sand or ASTM No. 9 stone also used for permeable joints application

- Equivalent to a traditional granular base under dynamic loads

- The interlocking panels distribute dynamic loads of up to 8 PSI (55 kPa) or 1152 lb (522 kg) on a 12″ x 12″ (30 cm x 30 cm) tile to a very wide area, practically eliminating any pressure on the ground

- LOCK-N-GO: designed with a tongue and groove system

- Better frost protection

- Less destructive to property during the construction phase

- Installing large Tile format

- Building; patios, walkways and pool surrounds

- Supporting an 18″ (45 cm) seating wall or fire pit

- Compatible with a heated paving system (up to 122°F (50°C))

- Staging tiles throughout the Gator Base

- To avoid stepping on setting bed

- Replaces a traditional granular base

- Completing job minimum 20% faster

- Tolerant against rain showers

- Watch our video

- All projects with difficult or easy access

- Up a hill

- Narrow workspaces

- Where construction speed is critical

- No industrial equipment required

- Areas with restricted access

- Stairs

- Narrow alleys

- Easy to use, install and transport

- Material storage is prohibited in streets

3

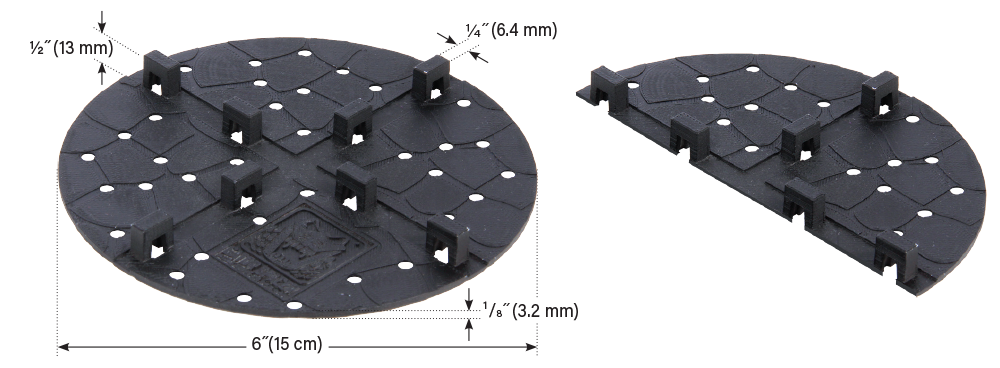

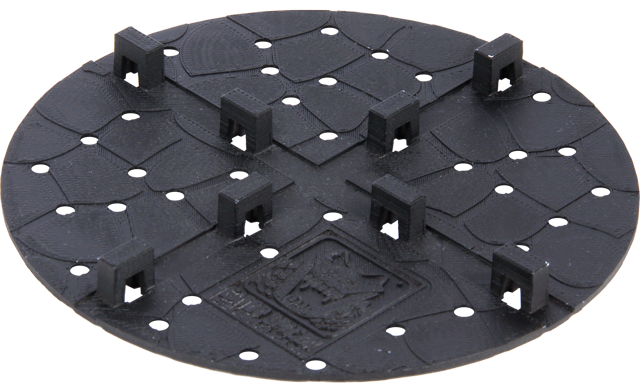

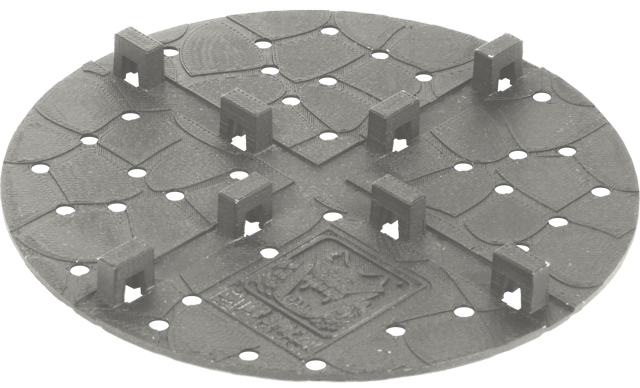

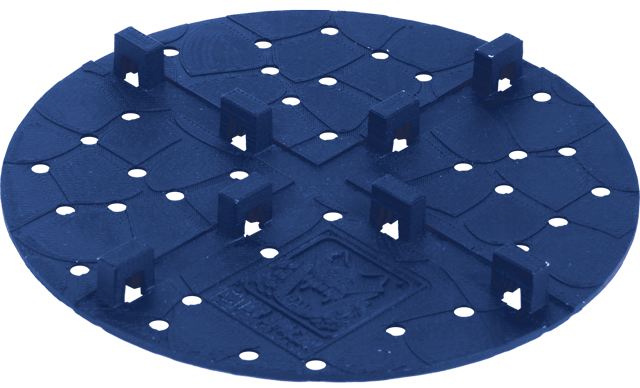

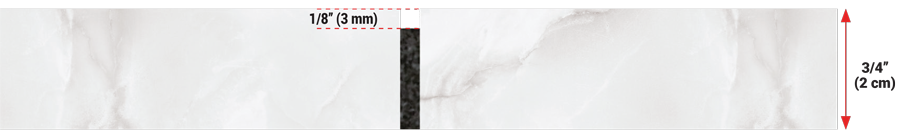

Provides uniform spacing and stability to the Gator Tile system.

- Porcelain tile installations

The spacer disk can be cut into either a half or a quarter-unit (using an utility knife) to be used along the edge of a building or the Gator Tile Edge. Simply break the spacer bar’s to obtain a flat disk, when spacer is needed on larger porcelain tile.

| Joint Size | Colors | |

|---|---|---|

| 1/4″ (6.4 mm) | Black |  |

| 3/16 (4.8 mm) | Grey |  |

| 1/8″ (3.2 mm) | Blue |  |

| Calculator | |

|---|---|

| 16″ x 16″ (40 x 40 cm) tiles sq. ft. × 0.4 = number of spacers (sq. m. × 4.3 = number of spacers) |

| 24″ x 48″ (60 x 120 cm) tiles sq. ft. × 0.35 = number of spacers (sq. m. × 3.77 = number of spacers) |

| 16″ x 32″ (40 x 80 cm) tiles sq. ft.× 0.75 = number of spacers (sq. m. × 8 = number of spacers) |

| 36″ x 36″ (80 x 80 cm) tiles sq. ft. × 0.29 = number of spacers (sq. m. × 6 = number of spacers) |

| Product | Joint Size | Units per pack | Packs per box |

|---|---|---|---|

| GATOR SPACER | 1/4″ – 3/16″ – 1/8″ (6.4 mm – 4.8 mm – 3.2 mm) | 50 | 6 |

4

Ensures mechanical binding and structural integrity of the system.

- Outdoor porcelain tiles

- Overlays and pool copings

- Fire pits (up to 400°F (204°C))

- Steps and wall caps

- Dry and damp surfaces

- Permanent Bond in 24 hours

- Long open time – repositioning up to 30 minutes

- Works above 32°F / 0°C

- High solids – provides excellent coverage

- Non-shrinking – does not crack or lose bond

- Xtra Bond Strength (up to 3 times the strength of conventional adhesives)

- Xtra Durability against torsion and tension

- Waterproof

- VOC compliant

- Low odor

| ADHESIVE STRENGTH CHART | 24 hours | 7 days |

|---|---|---|

| Concrete to concrete | 850 PSI | 1000 PSI |

5

The safety belt that will provide a strong lateral support.

- Reinforces the outside perimeter

- Creates a strong lateral support

- Will not corrode

- Easy-to-use

- Versatile

- Robust system

- Support strength

- Come in 8-ft (2.44 m) lengths

- Use with Gator Base Screws

6

The mechanical bond of the 2 main components on any Gator Base install.

Fastening Gator Tile Edge with the GATOR BASE SCREWS through the Gator Base reinforces the outside perimeter, creating a strong lateral support. GATOR BASE SCREWS are a required component on any Gator Base install.

- Fasten the Gator Tile Edge to Gator Base

- Locking all components into one

- Use with all Gator Base installation

- Use with all the Gator Edges: Rigid and Flex, Mini and Tile

- Reinforces the outside perimeter

- Creates a strong lateral support

- Locking all components into one

- Use GATOR BASE SCREWS to fasten Gator Edge to Gator Base

7

NITRO THE ONLY JOINTING SAND FOR OUTDOOR PORCELAIN TILE.

- Outdoor porcelain tile joints

- Pedestrian use

- Residential use

- Permeable

- Apply rain or shine

- Strength from top to bottom

- 25% More strength

- 25% Faster setting time

INSTALLATION INSTRUCTIONS

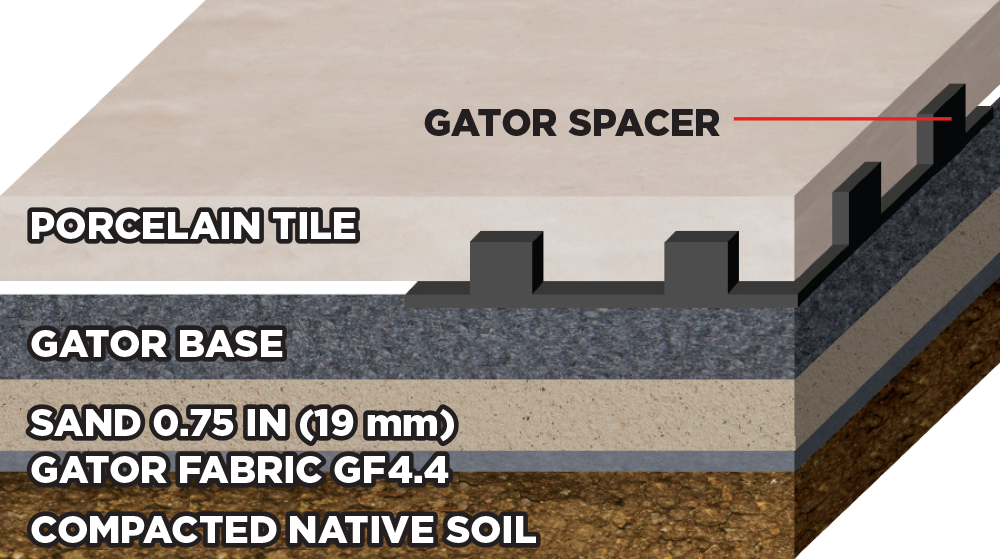

STEP 1 • Excavation of the new Gator Tile area

Excavate the new Gator Tile area. The depth required is calculated by adding Porcelain Tile height, Gator Base, Gator Spacer, bedding sand, plus any soft organic material that has to be removed. Excavate the perimeter an extra 6″ (15 cm) wider on all sides than the tile area required.

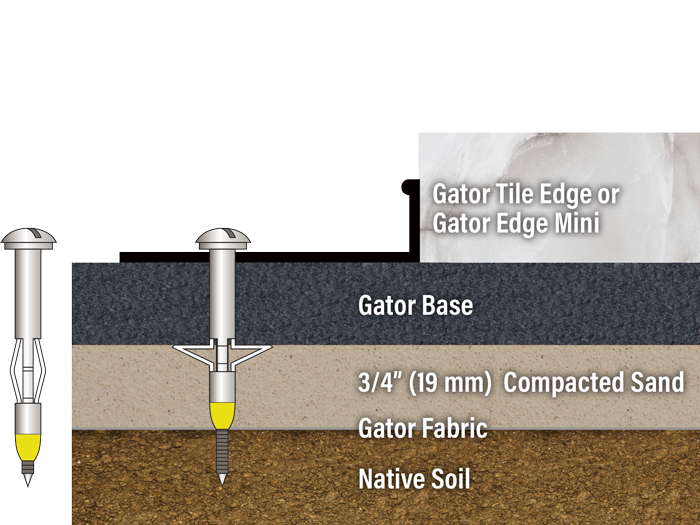

STEP 3 • Addition of Gator Fabric GF 4.4 (geotextile), levelling and compacted bedding sand

- Lay down a Gator Fabric GF4.4 and cover the entire excavated area.

- Spread an even layer of sand to a depth of maximum 3/4″ (19 mm) • The levelling and compacting of the bedding sand will be the last step prior to installing the Gator Base.

- Water the sand prior to using a hand compactor and/or plate compactor, compact the 3/4″ (19 mm) of bedding sand until you obtain a final height of 1/2″ (13 mm) of compacted bedding sand, that should reflect the final tiled surface.

- C-33 sand or ASTM No. 9 stone can be used as bedding material.

STEP 4 • Installation of the Gator Base

- Make sure to install the Gator Base on the extended excavation area (total excavation should be 6″ (15 cm) wider on each side than the final tiled area).

- Start laying the Gator Base units ensuring Gator Base interlocks with the tongue & groove system.

STEP 5 • Installation of Porcelain tile and Gator Spacer

Gator Spacers should receive a generous amount of Alliance polyurethane XP glue on each quadrant. Install the Porcelain Tile on the Gator Spacer, apply pressure or tap the tiles with a rubber mallet at all corners. This will ensure that the tiles are adhering to the Gator Spacer. The Gator Spacer will be left in the tile installation permanently, ensuring proper alignment and stability of your project for years to come.

STEP 6 • Installation of Gator Tile Edge and Gator Screws

Install Gator Tile Edge on the Gator Base using Gator Base Screws, make sure that Gator Tile Edge rests firmly against the tiles. Use Gator Base Screws at every second hole.